TROUVAY & CAUVIN, with decades of expertise in supplying high-quality piping solutions for the oil and gas and power industries, is now a trusted partner in the energy transition, supporting renewable and low-carbon energy projects worldwide.

We provide specialized and cost-effective material supply solutions for key energy transition projects, including:

Our extensive product portfolio includes low-carbon steel pipes, CRA piping, industrial valves and structural steel, ensuring efficiency, durability and compliance with the stringent standards of renewable energy projects.

With a robust global supply chain network and extensive project expertise, TROUVAY & CAUVIN delivers tailored material solutions to meet the evolving demands of renewable energy infrastructure. We support EPC contractors, developers and project owners in sourcing reliable and sustainable materials that align with energy transition goals.

Concentrated Solar Power (CSP) plants are an efficient and sustainable solution for harnessing solar energy to generate electricity. With the ability to store thermal energy for continuous power generation, CSP technology is becoming a key component in the energy transition.

Countries across the MENA region are prioritising CSP technology to diversify their energy mix and reduce carbon emissions. As a proven method for large-scale solar power generation, CSP plants play a crucial role in advancing low-carbon and renewable energy initiatives.

TROUVAY & CAUVIN provides a portfolio of standard and customised products designed for the heat transfer fluid (HTF) systems used in CSP plants. Our solutions include:

With extensive experience in supplying materials for renewable energy projects, TROUVAY & CAUVIN offers reliable, high-performance solutions to support the development and expansion of CSP plants. We work closely with EPC contractors and project developers to ensure efficient and cost-effective material supply for solar energy infrastructure.

Biofuels are emerging as a sustainable energy alternative, providing clean liquid fuels that address rising energy costs, energy security concerns and carbon emissions. In many developing countries, interest in biofuel production is increasing due to its ability to reduce dependence on fossil fuels while utilising forestry and agricultural residues. As a result, biofuel plants are primarily developed in agricultural regions with consistent access to biomass resources.

As a leading supplier of pipes, valves and fittings (PVF) for the energy and industrial sectors, TROUVAY & CAUVIN provides high-quality materials designed to withstand the chemical and thermal processes involved in biofuel production. Our supply includes:

With extensive experience in supporting renewable energy projects, TROUVAY & CAUVIN delivers tailored material supply solutions for biofuel plants, ensuring efficiency, reliability and compliance with industry standards. We work closely with EPC contractors, biofuel producers and engineering teams to provide cost-effective and durable solutions for biofuel infrastructure development.

Wind farms play a vital role in the global transition to clean energy, offering one of the most cost-effective renewable energy sources. Offshore wind farms, despite being smaller in scale compared to oil and gas production platforms, require similar high-performance materials due to the harsh marine environment and structural demands of offshore installations.

With extensive experience in supplying structural steel for offshore oil and gas projects, TROUVAY & CAUVIN is a trusted supplier for offshore wind farm construction. We provide high-quality structural steel materials that meet the strict offshore specifications required for renewable energy infrastructure.

Our comprehensive inventory includes materials suitable for:

With a large stock of offshore-grade structural steel, TROUVAY & CAUVIN ensures efficient supply chain management, allowing for timely delivery to support the construction, expansion and maintenance of offshore wind farms.

With a proven track record in offshore structural steel supply, TROUVAY & CAUVIN provides tailored solutions for wind farm developers, EPC contractors and renewable energy operators. We offer reliable, high-performance materials that comply with stringent offshore industry standards, ensuring durability, sustainability and cost-efficiency in offshore wind energy projects.

Hydrogen is increasingly recognised as a clean energy source, playing a pivotal role in the global energy transition. As a low-carbon and carbon-free energy carrier, hydrogen offers versatile applications and can be produced using green energy sources such as electrolysis or through conventional methods like steam methane reforming (SMR) with carbon capture.

Transporting hydrogen via pipelines shares similarities with natural gas transportation, an area where TROUVAY & CAUVIN has extensive expertise. However, due to hydrogen’s unique properties, including high diffusivity and reactivity, pipeline materials must meet strict specifications for durability, corrosion resistance and operational safety.

We provide cost-effective PVF (pipes, valves and fittings) solutions for:

With a proven track record in energy infrastructure supply, TROUVAY & CAUVIN offers tailored hydrogen piping solutions that ensure safe, durable and efficient operation. We work closely with EPC contractors, hydrogen producers and infrastructure developers to deliver reliable and compliant materials that support the growth of the hydrogen economy.

Geothermal energy is a clean and renewable energy source generated from heat stored deep beneath the earth’s surface. As a low-emission and sustainable alternative, geothermal power plays a vital role in the global energy transition, providing reliable baseload power generation with minimal environmental impact.

Every geothermal power plant requires a robust network of pipelines to transport high-temperature geothermal fluids from production wells to power generation units. These pipelines must be engineered to withstand extreme temperatures, high pressure and corrosive environments. Key pipeline components include:

With extensive expertise in supplying high-performance piping solutions, TROUVAY & CAUVIN provides corrosion-resistant pipes, valves and fittings (PVF) for the entire geothermal power plant infrastructure. We offer:

As a leading supplier for renewable energy projects, TROUVAY & CAUVIN delivers tailored material solutions to support the development and expansion of geothermal power plants. We work closely with EPC contractors, geothermal operators and project developers to ensure the seamless integration of high-performance materials in geothermal infrastructure.

Nuclear energy is a low-carbon and highly efficient power source, playing a crucial role in the global energy transition. As the world seeks sustainable and long-term energy solutions, nuclear fusion is emerging as a game-changing technology, capable of producing virtually limitless cleaner energy by replicating the fusion reactions of the sun.

ITER (Latin for ‘The Way’) is the largest experimental fusion reactor in the world, located in the south of France. This international research and engineering megaproject brings together 35 nations working collaboratively to build the world’s largest tokamak, a nuclear fusion reactor designed to harness fusion energy for power generation.

Since 2017, TROUVAY & CAUVIN France has been privileged to be among the selected suppliers providing high-quality materials for this prestigious scientific endeavour. As a key partner in nuclear energy infrastructure, we offer specialised materials that meet the strictest quality, safety and regulatory requirements for nuclear fusion projects.

We supply Carbon Steel and Stainless Steel plates, beams, hollow sections and profiles, meeting the construction demands of various departments within the ITER project. Our materials are used in critical structural components, contributing to the safety, stability and efficiency of the fusion reactor and supporting infrastructure.

With decades of experience in supplying high-performance materials for the energy sector, TROUVAY & CAUVIN is committed to supporting nuclear power advancements. We work closely with EPC contractors, nuclear research institutes and energy developers to provide reliable, compliant and precision-engineered materials for nuclear infrastructure.

Carbon Capture Utilisation and Storage (CCUS) is a key technology in the fight against climate change, enabling the capture of CO₂ emissions before they enter the atmosphere. The captured carbon can either be used commercially in industrial applications or permanently stored underground to help reduce carbon emissions and meet global energy transition targets.

TROUVAY & CAUVIN provides a wide range of high-performance piping solutions for every stage of the CCUS process. With extensive experience as a leading supplier of pipes, valves and fittings (PVF) for the oil and gas sector, we offer technical expertise and competitive solutions to support EPC contractors and end-user customers in their CO₂ capture and storage initiatives.

Our CCUS material solutions include:

As the global energy industry moves towards low-carbon solutions, TROUVAY & CAUVIN is committed to supporting CO₂ reduction efforts with tailored material supply solutions. We work closely with EPC firms, energy companies and industrial operators to provide cost-effective and compliant products that meet the stringent requirements of CCUS projects.

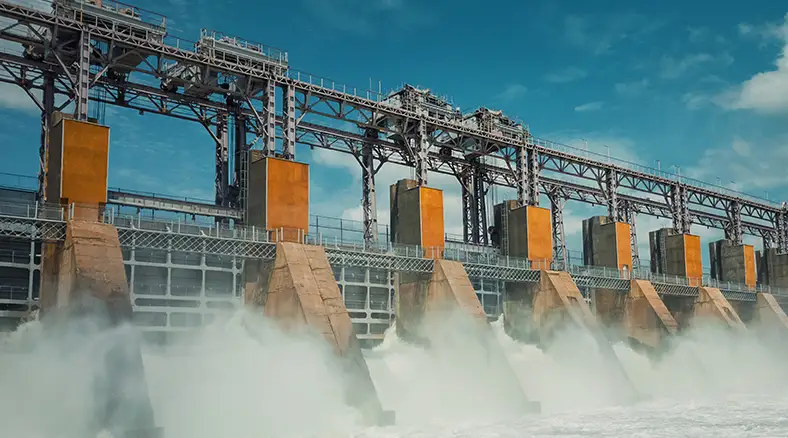

Hydropower is a clean, reliable and cost-effective energy source, offering sustainable power generation while providing multiple non-energy benefits, including flood control, irrigation and water supply. As one of the most widely used renewable energy sources, hydropower plays a crucial role in global energy security.

With extensive experience in water supply, storage and water treatment projects across the world, TROUVAY & CAUVIN has the expertise to identify and supply high-quality materials tailored for hydropower plants and large-scale water infrastructure. We provide cost-effective and technically compliant solutions designed to meet the stringent demands of hydropower facilities.

Our supply solutions for hydropower projects include:

With a proven track record in renewable energy and water projects, TROUVAY & CAUVIN is committed to delivering tailored material supply solutions that support the construction, expansion and modernisation of hydropower plants. We work closely with EPC contractors, project developers and water authorities to provide innovative and sustainable solutions for large-scale hydropower infrastructure.

The use of biomass and waste resources for power generation is rapidly growing due to its CO₂-neutral emissions, resource availability, base load capability and economic benefits. As a renewable energy source, biomass is increasingly adopted in agricultural countries such as the United States, United Kingdom, China, India, Germany, Thailand and Italy, where sustainable energy solutions are in high demand.

With a strong global presence, TROUVAY & CAUVIN leverages its regional offices, logistics platforms and storage yards to efficiently meet the demands of biomass and waste-to-energy projects. We provide cost-effective and technically compliant solutions, supporting customers with high-quality materials and expert project assistance.

Our biomass energy supply solutions include:

As a leading global supplier to the energy industry, TROUVAY & CAUVIN not only supplies essential PVF materials but also offers comprehensive value-added services to support biomass power plant operators, consultants and contractors. Our tailored services include:

With extensive expertise in renewable energy projects, TROUVAY & CAUVIN is committed to delivering reliable and cost-effective solutions for biomass and waste-to-energy facilities. We collaborate with EPC contractors, project developers and plant operators to supply high-performance materials that meet the stringent requirements of biomass energy infrastructure.