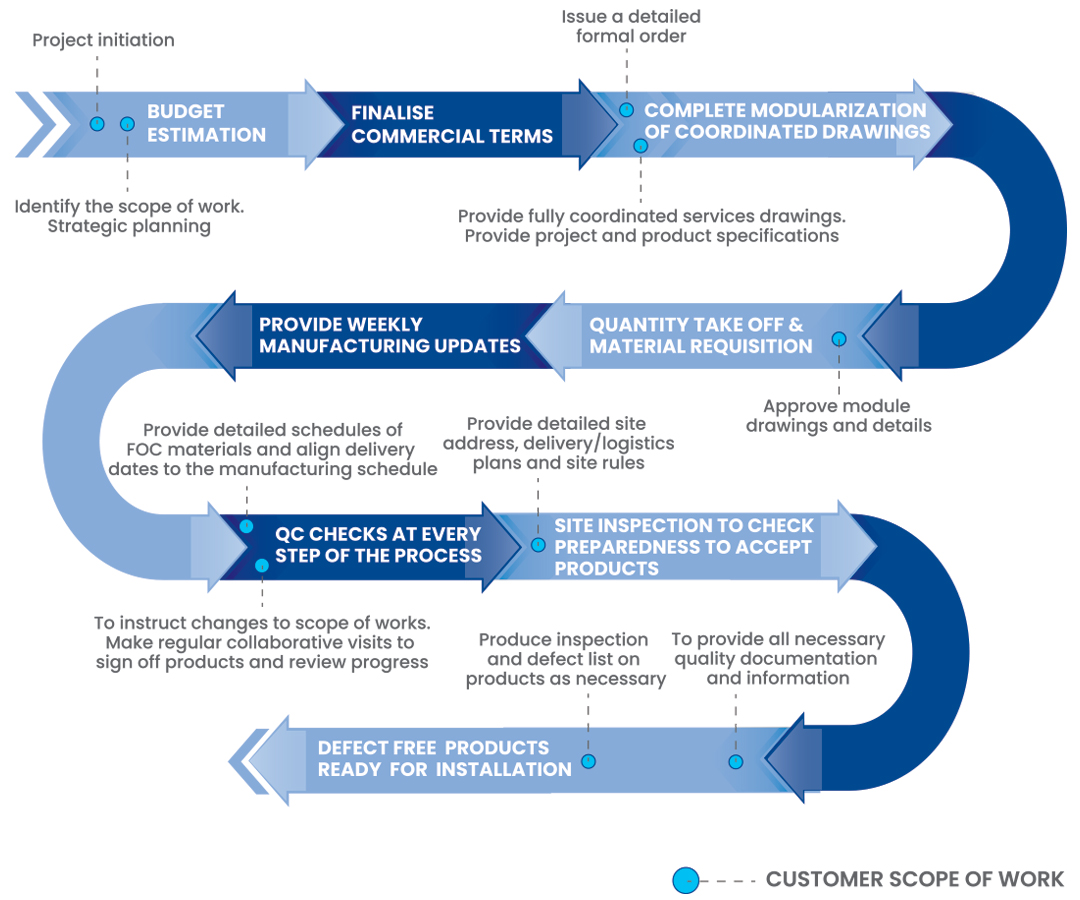

The construction industry is evolving rapidly, embracing modern methods that enhance efficiency, sustainability, and cost-effectiveness. Offsite prefabrication is at the forefront of this transformation, delivering faster project timelines, improved quality control, and significant cost savings.

At TROUVAY & CAUVIN, we are driving this industry shift with our state-of-the-art Offsite Prefabricated Solutions. Our solutions offer a wide range of benefits, including:

Our cutting-edge facility in Jebel Ali, Dubai, specializes in the fabrication of single-service and multi-service MEP modules, integrating the latest engineering technologies under strict factory-controlled conditions.

The TROUVAY & CAUVIN Group’s long-standing relationships with the world’s leading manufacturers, combined with our procurement expertise, give you access to the highest quality piping materials, valves, fittings and offsite prefabrication solutions.

Many of the world’s leading contractors rely on the TROUVAY & CAUVIN Group to deliver high quality piping solutions for their construction, water and infrastructure projects.

Not only is our Jebel Ali plant triple certified (ISO 9001, ISO 14001, ISO 45001), but our long-standing relationships with key manufacturing partners such as V&M, Saint Gobain, Armstrong, Devatec, Cephas Valves and Victaulic give the TROUVAY & CAUVIN Group an edge that sets us apart from the competition.

Without our value-added services offering, we would not be a true packer. TROUVAY & CAUVIN Group offers a comprehensive range of services to simplify your project requirements: wrapping, cutting, grooving, painting, sandblasting, assembly, valve actuation, commissioning and maintenance are just a small selection of what we offer.

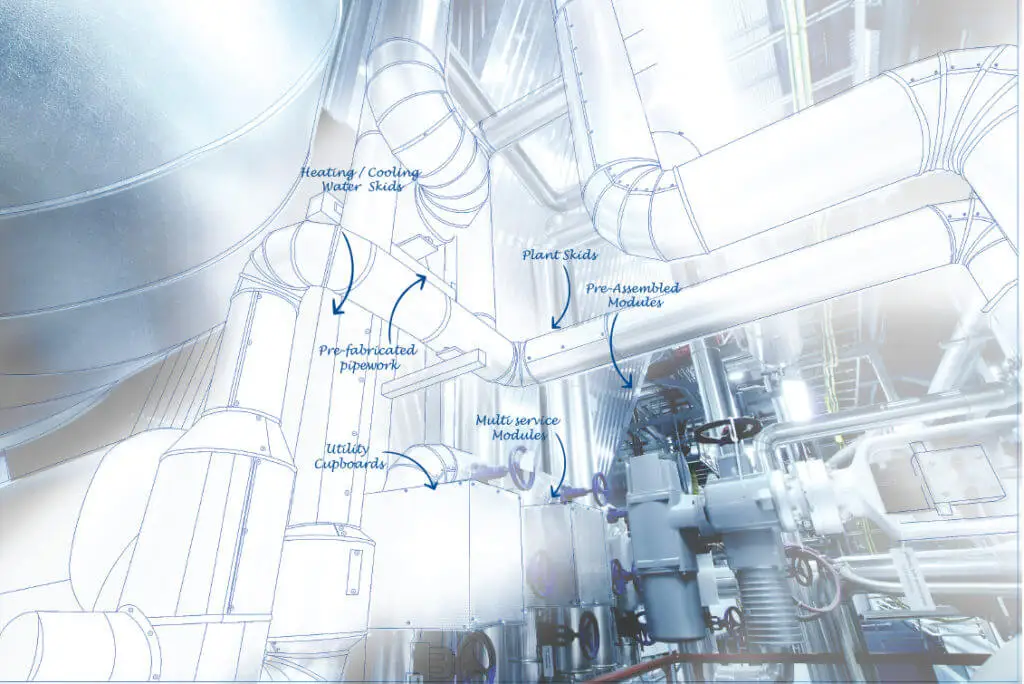

Our Product Range for Offsite Prefabricated Solutions

TROUVAY & CAUVIN boasts a sprawling 30,000-square-metre facility in Jebel Ali, Dubai, featuring a cutting-edge 6000-square-metre covered warehouse and a fully equipped offsite prefabrication workshop.

Key Features:

Why Choose TROUVAY & CAUVIN?

Advanced Offsite Prefabrication Workshop

Our workshop offers a wide range of services, including pipe finishing, manual and machine cutting, threading, beveling, grooving, shot blasting, painting, coating, welding, color coding, bar coding, and packing.

For tasks not performed in-house, we subcontract to qualified local suppliers under TROUVAY & CAUVIN’s strict supervision to guarantee fast delivery times and high-quality standards.

Faster construction with time savings of up to 60%. Onsite and Offsite work is carried out simultaneously, making more efficient use of skilled labour.

Because most of the work is done in a factory-controlled environment, accuracy is higher and error is less likely. Improved quality controls at every step.

Thanks to the readily available stock in our yards, the prefabrication process can begin as soon as the designs are approved, without losing time in ordering and receiving materials.

Construction sites are safer and more conducive as most work is done offsite, and less time is spent working at height

Significant reduction in dust, and noise pollution. Onsite waste can be virtually eliminated and any waste produced can be controlled and recycled.

Improved cost productivity. The use of standardised products can lead to economies of scale and reduce the need for onsite manpower, tools and equipment...

High level of customization and flexibility. Optimization of schedule and costs. Improve Onsite Collaboration and Communication.

Unaffected by weather conditions or other trades, Prefabricated modules provide overall reduction in schedules and greater certainty of delivery.

Ground-up installation of MEP modules eliminates many connection problems. Since onsite work only consists of connecting MEP modules to mains, there is minimum damage to components.

Reduced failure rates and more reliable asset performance helps to reduce opex cost over the life of the asset.