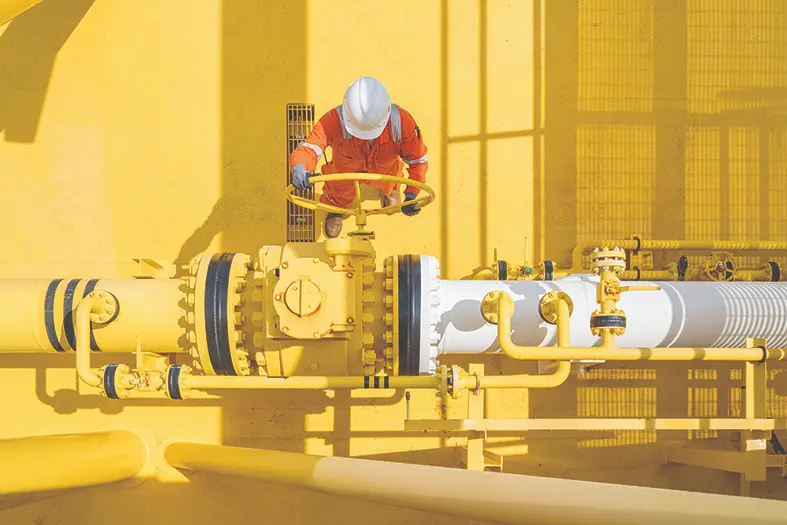

With TROUVAY & CAUVIN’s extensive knowledge and experience, we are well equipped to deliver precise and reliable steam and condensate solutions for your network. Our specialists are trained to help you improve the reliability and performance of your utility system through ongoing inspection, repair, replacement and routine maintenance of your steam assets.

Steam generation, distribution and consumption analysis

Condensate recovery analysis

Steam traps surveys

Flash steam recovery

Reliable, accurate trap surveys by our trained, certified technicians

Tools and training to help you conduct your own surveys more accurately and efficiently

Expert diagnosis of issues encountered at site

Innovative products and technologies for accurate system monitoring and effective steam trapping

Water hammer detection, analysis and elimination

Improved drainage of flooded heat exchangers

Improved steam quality

Energy audits to detect defective or leaking traps, identify the cause of any failures and find ways to reduce your energy consumption

Analysis of system deficiencies and advice on simplifying, optimising and increasing the reliability of your trap stations

Implement best practices for water hammer, scalding, discharge etc.

Address critical safety issues in boiler rooms, hot water tanks, heaters and other equipment and areas where steam and condensate solutionsplays an important part.

Consider all safety issues while maintaining proper steam and condensate management systems

Calculation of the current financial and energy losses and the corresponding CO2

Return On Investment (ROI) estimate based on the average cost of equipment and labour.

Propose improvements and timelines, based on target ROI.

Analyze and monitor data collected by the plant

Analyze each part of the steam system ( from generation to condensate return) and predict how altering any would affect the system

Create a guideline for areas where energy or operational improvements can be made

Maintain the results already achieved and warn of possible dangers

or undesirable events

Operations and maintenance services to manage your utilities more efficiently

Tailor-made maintenance contracts that meet the client’s requirements and keep budgets in mind

The TROUVAY & CAUVIN Group offers a wide range of services for the operation and support of plant valves to ensure continuous and stable operation throughout the life of the plant. With a vast, hands-on experience over the years, we can provide solutions to improve the performance of the plants, save costs, extend service life, and improve productivity as well as efficiency.

Survey and automation of manual valves in service

Design, fabrication and installation of stem extension kits on existing valves

Valve modification to solve access issues

Evaluate and raise awareness of potential hazards and risks in the plant

Comprehensive analysis and regular risk assessment studies to determine the required maintenance and repair of the facility

Trained and experienced technicians who carry out on-site inspections, tests and repairs on valves and associated safety systems

Replacement of obsolete or defective actuators and sensors

Emergency services for critical applications

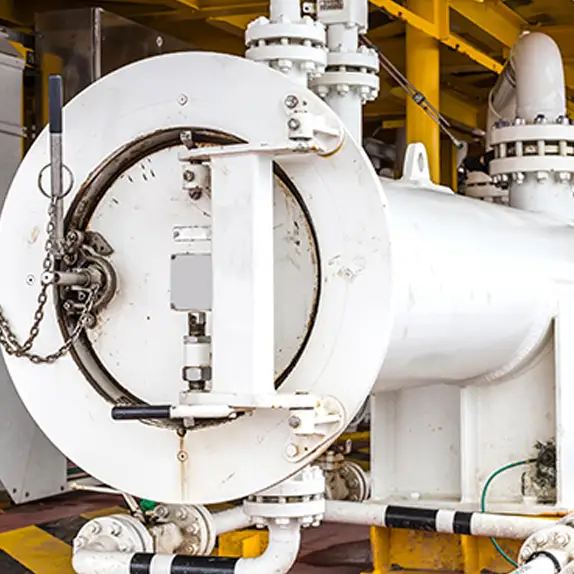

Identify the right smart pigging system for the pipeline and calculate the ROI

Integration of smart pigging system into the pipeline

Our team of qualified engineers provide technical and service support for flame arrestors installed at site. This includes regular inspection, maintenance and replacement of original spare parts and other components susceptible to friction and corrosion.

We are an authorised service partner for well-known flame arrestor manufacturers and carry out onsite safety audits of flame arrestors and ensure that they are correctly installed in accordance with the latest HSE guidelines.